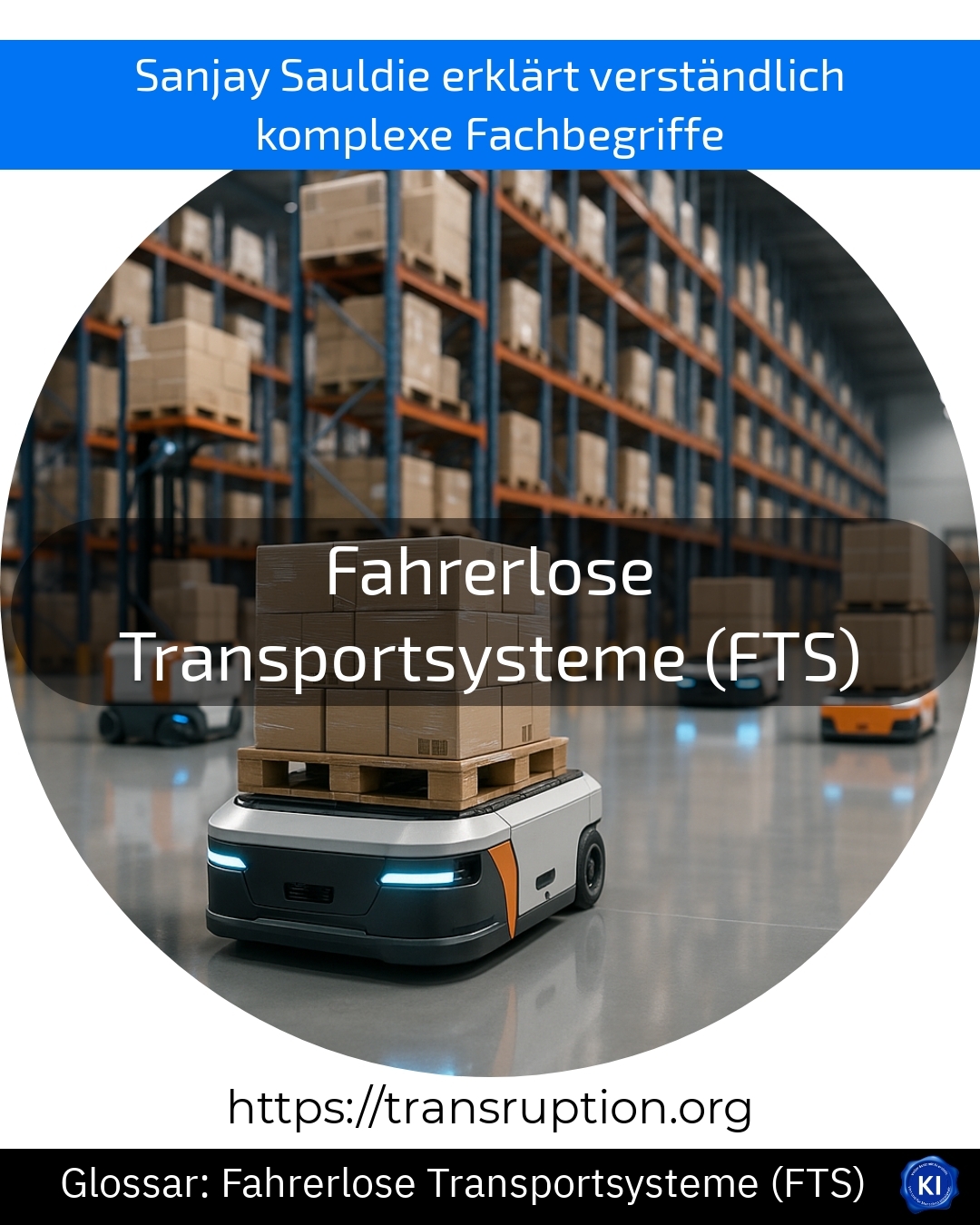

The term "automated guided vehicle systems (AGV)" is primarily used in the fields of automation, industry and Factory 4.0 as well as robots. Automated guided vehicles are vehicles that independently move goods or materials in factories, warehouses and other operations - without the need for a human driver.

The AGVs recognise their surroundings using sensors and navigation systems. They travel fixed routes or adapt their paths flexibly to avoid obstacles or react to new tasks. The aim is to make work processes more efficient, faster and safer.

An illustrative example: In a modern car production facility, an AGV automatically transports components from the warehouse to the assembly station. Meanwhile, the team continues to work on the vehicles without losing time for logistical tasks. In this way, automated guided vehicles help to optimise processes and relieve employees.

AGVs are an important component of Industry 4.0, enabling companies to save costs, avoid errors and increase their competitiveness. Thanks to modern technology, the systems are flexible and can be easily adapted to changing requirements.